LEAN: Eliminate waste

Lean is a management philosophy that focuses on eliminating waste in order to offer added value to the customer. We focus in particular on reducing the lead time, whereby the production quality is increased and the production costs are lowered. The principle comes from Japan where the founder of Toyota, Sakichi Toyoda, his son Kiichiro Toyoda and engineer Taiichi Ohno have largely developed this methodology.

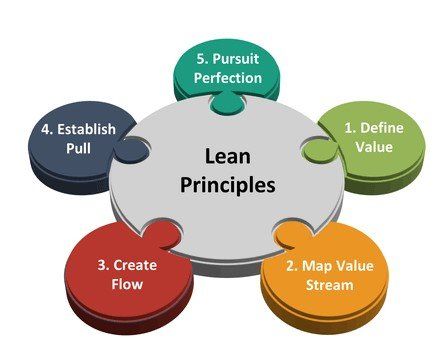

Womack and Jones are also two well-known names in the Lean world. During their many years of research at Toyota, they have uncovered the 5 steps of lean working, which is still the starting point for improving processes;

1. specify the customer value

The key question underlying this principle is: Who are our customers and what do they actually expect us to deliver?

2. analyze the value flow

a one-page overview containing all processes that take place within the organization, possibly including their mutual relationship. A distinction is made between controlling, primary and supporting processes. A workflow folder (VSM) is then created for each process, indicating added value.

3. Streamline the processes

In an ideal situation, streamlining processes leads to all process steps being arranged in such a way that they take up the same amount of time. In this way, the end result of one process step can be immediately passed on to the next process step after completion, creating nowhere a queue or stock (one of the 7 wastes)

4. Work demand sent

An elaboration of this principle is the one-stop shop, where customers are helped with all their questions in one go. In a hospital, this means that patients only have to go to the hospital once to undergo the entire treatment process, rather than having to come multiple times for different treatment steps.

5. pursue perfection

• Work without errors

• Work without stock

• Work on cost reduction

• Provide an endless variety of services

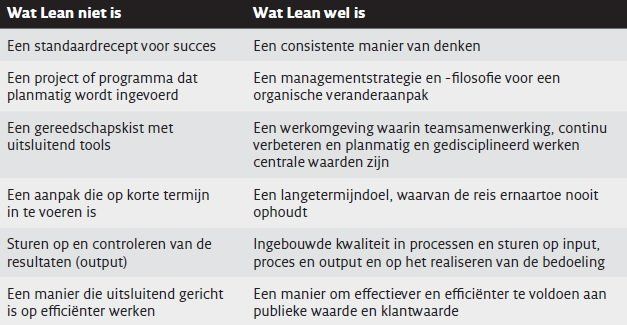

The basic principles of Lean Management are fairly easy to understand, which makes the implementation easily accessible. This is also where the pitfall lies, Lean is a continuous process in which thinking patterns often have to change during implementation. This requires good training and professional guidance in which QMS Improvement can fully guide and advise you.

CONTACT

31 (0) 621 271 420

info@qms-improvement.com

Snipe 48, 4617JK Bergen op zoom